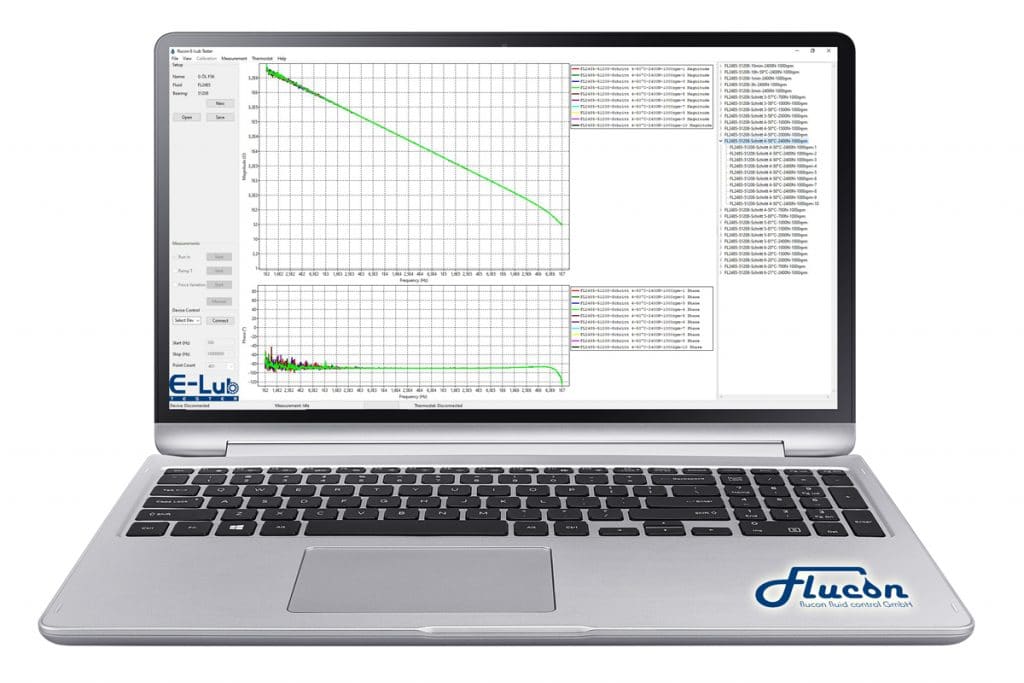

Presenting the all-new “E-Lub Tester” for electric analysis of bearings and lubricants.

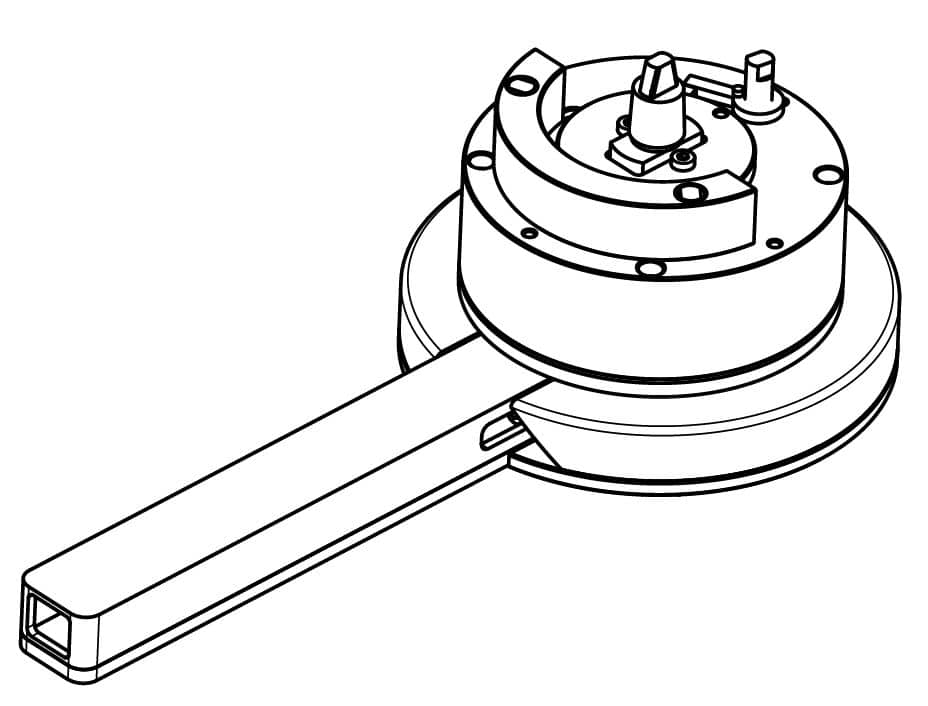

Based on previous knowledge of the technology of our EPSILON+ laboratory system, our team has designed a novel measurement and test setup for the four-ball tester (FBT), which can be used to investigate the behavior of electrically loaded rolling bearings.

In addition to the impedance, the E-Lub Tester is to be used to investigate the damaging breakdown currents and, in the future, to enable a statement to be made on the lubrication gap height or the lubrication condition in the bearing under certain load conditions without having to resort to the known model calculations for this purpose.

The E-Lub Tester with its completely new test spectrum is suitable for numerous fields of application, e.g.:

- lubricant development,

- bearing development,

- development of electric drives,

- railroad, wind turbine and gearbox technology.

The E-Lub Tester is used to test oils and greases used in rolling bearings. Using the 51208 axial deep groove ball bearing, a lubricant can be analyzed as a function of variable process conditions (temperature, speed, mechanical load, electrical voltage, operating hours).

The E-Lub Tester is used to test oils and greases used in rolling bearings. Using the 51208 axial deep groove ball bearing, a lubricant can be analyzed as a function of variable process conditions (temperature, speed, mechanical load, electrical voltage, operating hours).