CGS Inline Aeration Meter

Aeration measurement has never been so easy.

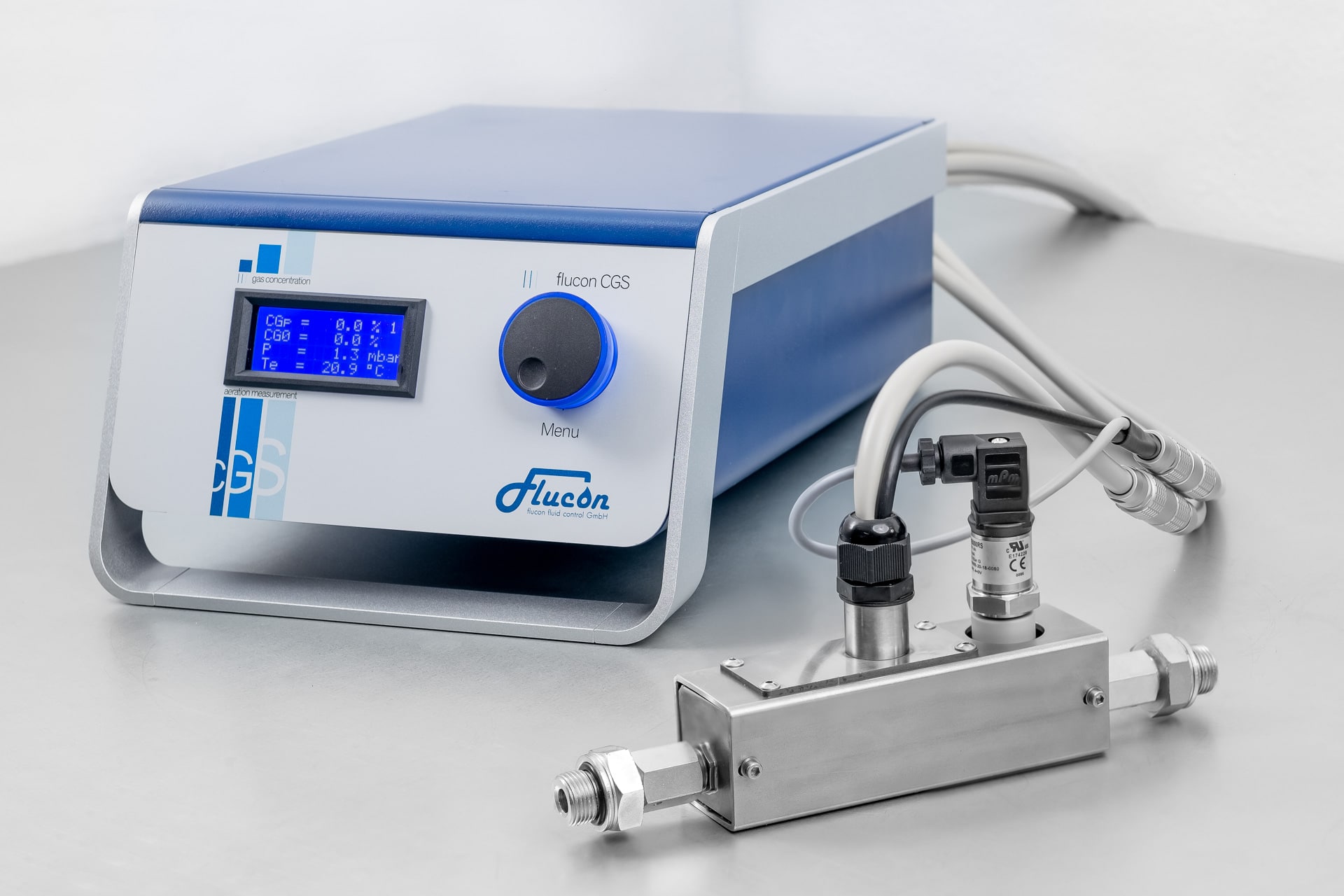

The core element of our CGS (Concentration Gas System) inline aeration meter is a measuring tube without any mechanically moving parts. The determination of the gas concentration (CG) in two-phase flows is based on an innovative procedure which, in contrast to the radionuclide method, is hazard-free.

Measuring the change of the complex fluid impedance in comparison to the unaerated medium, CGS offers decisive advantages in all fields of application concerning the gas concentration. Whether it's oil aeration in engines or gear boxes, foamed adhesives or aerated food products: Our CGS is the perfect tool for almost every gas-in-fluid problem.

Another advantage of the CGS is its high resolution. No matter if you have microbubbles of minimum diameters or larger air pockets entrained in your oil: our system allows you to get accurate gas content measurements independently of both the physical form and the flow conditions of your two-phase mixture. Thanks to its integrated pressure sensor you can always compare your results through the additional standardized CG0 value, which equals the gas concentration at atmospheric pressure.

Key features

- Compact, wear-free and highly accurate fluid aeration meter for inline installation

- Continuous displaying of the aeration / concentration of undissolved gas in fluids

- Constantly high accuracies from 0.10 to 100.00 vol% of gas

- Inline measurement without any mechanically moving parts

- Suitable for all electrically non-conductive types of liquids (cond. < 600 nS/m)

- Can be used for mainstream and bypass measurement

- Fully upscalable system: different sensor sizes available for different flow rates

- Non-destructive, hazard-free measurement, independent of the direction of flow

- Integrated temperature and pressure measurement

- 4 Output values: Temperature; Pressure; CGp (live gas concentration at measured pressure); CG0 (standardized value of gas concentration at atmospheric pressure)

- Comparative results due to retroactive accounting of the equivalent gas concentration at atmospheric pressure

- Fast measuring rates (1 Hz and 10 Hz version available)

- simple and intuitive handling

- Portable measuring instrument (110-240 V AC and 9-36 V DC version available)

- Standard digital interface (RS-232, adaptable to USB) for an optional connection to your WINDOWS PC

- intuitive flucon software included

- Analog output (4...20 mA or 0...10 V) of all measured values

Fields of application

The standard sensor of the CGS is equipped with two UNF 9/16" connectors* and can easily be integrated into your fluid circuit. Due to its continuous inline measurement of the volumetric gas concentration in fluids our system offers new possibilities, e.g. for the continuous inline monitoring of oil aeration in hydraulic pipes, combustion engines, turbochargers or gear boxes, or for the optimized application of aerated adhesives.

The CGS aeration meter can furthermore be applied as a control unit in areas of technical production which require gas contents as an important quality feature, or in areas in which the systematic introduction of gas can reduce production costs.

The following fields of application summarize the versatility of the CGS:

- Inline live data

Survey and control the important criterion of oil aeration for the design of oil pumps, motors, turbochargers or gear boxes.

- Optimization of machines and machine parts

Design new machine elements with reduced oil aeration.

- Optimization of fluid development

Develop fluids with optimized aeration and degassing behavior.

- Process survey and control

Optimize processes in the application of aerated fluids and adhesives.

(* BSP 3/8" male adapters included, other screw-on adapters available upon request)

Composition

In general the CGS aeration meter consists of only two components: the measuring tube with three integrated sensors (CG sensor, PT100 temperature sensor and pressure sensor) on the one hand, and the corresponding control and evaluating system in an electronic unit on the other hand.

In general the CGS aeration meter consists of only two components: the measuring tube with three integrated sensors (CG sensor, PT100 temperature sensor and pressure sensor) on the one hand, and the corresponding control and evaluating system in an electronic unit on the other hand.

Sensor

Both ends of the standard sensor (left picture) are equipped with UNF 9/16" (dash 6) connectors which can be adapted to 3/8" or other standard fittings and which simplify the mounting of your measuring instrument into your fluid circut. The standard sensor is suitable for main stream installation with 0.5 - 5 l/min (< 1.3 gpm). If your application has higher flow rates we recommend bypass installation with the optional bypass installation kit. However, if main stream measurement is preferred, there is a large sensor available as well.

Electronics

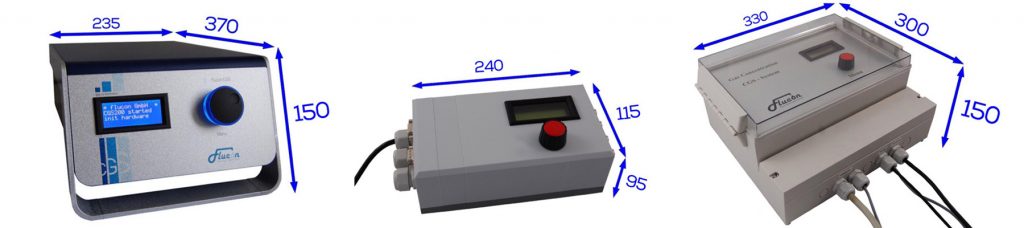

There are different types of electronic units / housings available: as alternatives to the aluminum desktop housing (bottom left) with separable LEMO connectors we offer a small compact housing for mobile use (bottom center), as well as a large plastic housing with terminals (bottom right) which is designed for control cabinet installation.

Each CGS is available either for 110-240 V AC or for 9-36 V DC supply. Thus on-board applications, e.g. with a 12 V battery supply, can be realized with ease as well.

Fast or superfast measurement?

Once you have decided which sensor and electronics may be ideal for your application, there is one more thing to figure out: Would you like to measure at standard speed - once per second - or at high-speed - ten times as fast?

With a measuring time of only 100 ms the CGS in high-speed version might come in handy, especially if you have a highly dynamic application with higher flow rates or with an unsteady and inhomogeneous aeration.

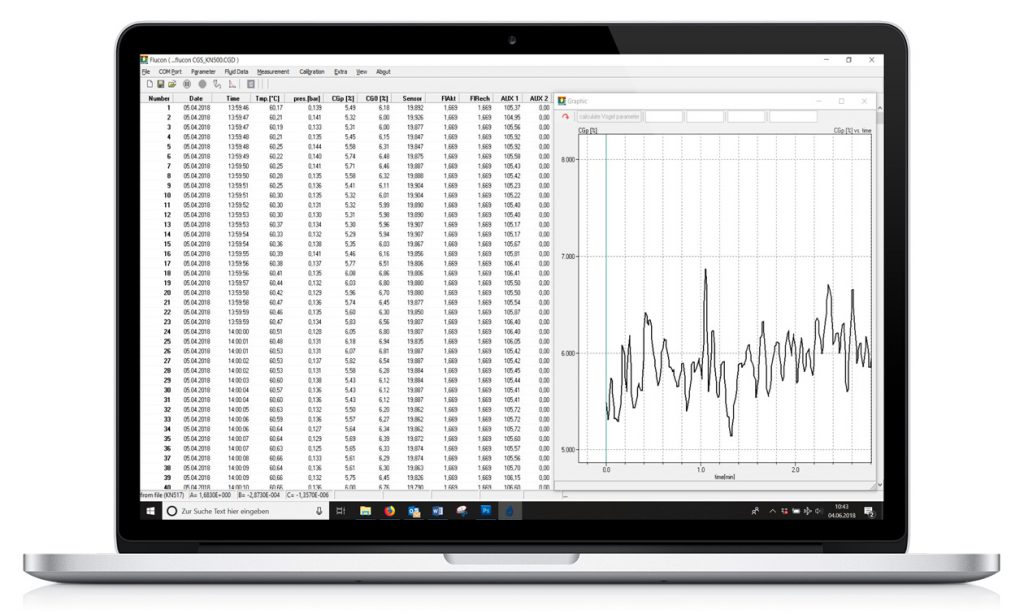

Operating your CGS aeration meter

No matter the type of sensor or electronics, or if it's a standard or a high-speed version: every CGS system can be used in stand-alone mode or can be operated with your WINDOWS computer via RS-232/USB. Each system comes with the powerful CGS software that enables you to survey and interpret your measurements.

If you prefer controlling your data with your master computer, you can simply use the analog output of the CGS (0...10 V or 4...20 mA) to transfer the measured live data of all relevant parameters.

Calibration

Getting started with your aeration measurement is quite easy: Before first usage the CGS only needs to be calibrated once on your specific unaerated oil. This should be done over the full temperature range of your process, with +/- 10°C of recommended extra range. For measuring with various fluids the CGS has a fluid list which allows you to save up to 20 different oils (sets of parameters). This enables you to quickly switch the presaved parameters by use of the menu, e.g. to use the sensor on another testbed that contains a different type of oil.

To make the calibration easier we offer optional fluid thermostats that can be controlled by the CGS system.

Technical data of the CGS

| Measuring range | 0 to 100 vol% Gas |

| Accuracy | approx. +/- o.1 vol% Gas |

| Measuring media & Flow rates | electrically non-conductive fluids

for flow rates < 5 l/min (1.3 gpm): use standard sensor for higher rates: use bypass installation or large sensor customized sensor tubes for main stream installation also available upon request |

| Measuring time | Standard: approx. 1 s,

high-speed version (measuring time approx. 100 ms) available upon request |

| Temperature measurement | PT 100, +/- 0.1 °C |

| Temperature range | -30°C to 150°C |

| Pressure range | max. 10 bar |

| Dimensions measuring tube (WxHxL) | Standard sensor: 40 x 110 x 165 mm;

Large sensor: 60 x 127 x 218 mm custom-made sizes available upon request |

| Material measuring tube | special steel (1.4571) |

| Connection | Standard sensor: 2x UNF 9/16″-18Gg (dash-6) male

screw-on adapters (G 3/8" or others) available upon request; Large sensor: 2x G1" female; |

| Dimension electronic unit (WxHxD) | Standard (Aluminum): 235 x 150 x 370 mm

Large (with connecting terminal): 330 x 150 x 300 mm Compact (for mobile applications): 240 x 95 x 115 mm |

| Data communication (computer) | RS-232 interface (CGS software for WINDOWS included) |

| Analog output temperature | 4-20 mA / 0-10 V |

| Analog output CGp-signal | 4-20 mA / 0-10 V |

| Analog output CG0-signal | 4-20 mA / 0-10 V |

| Analog output pressure | 4-20 mA / 0-10 V |

| Power supply | 110-240 VAC or 9-36 VDC |

Contact us today

Are you interested in accurate air content measurement ?

Please contact us for further information or technical discussion.