E-Lub Tester

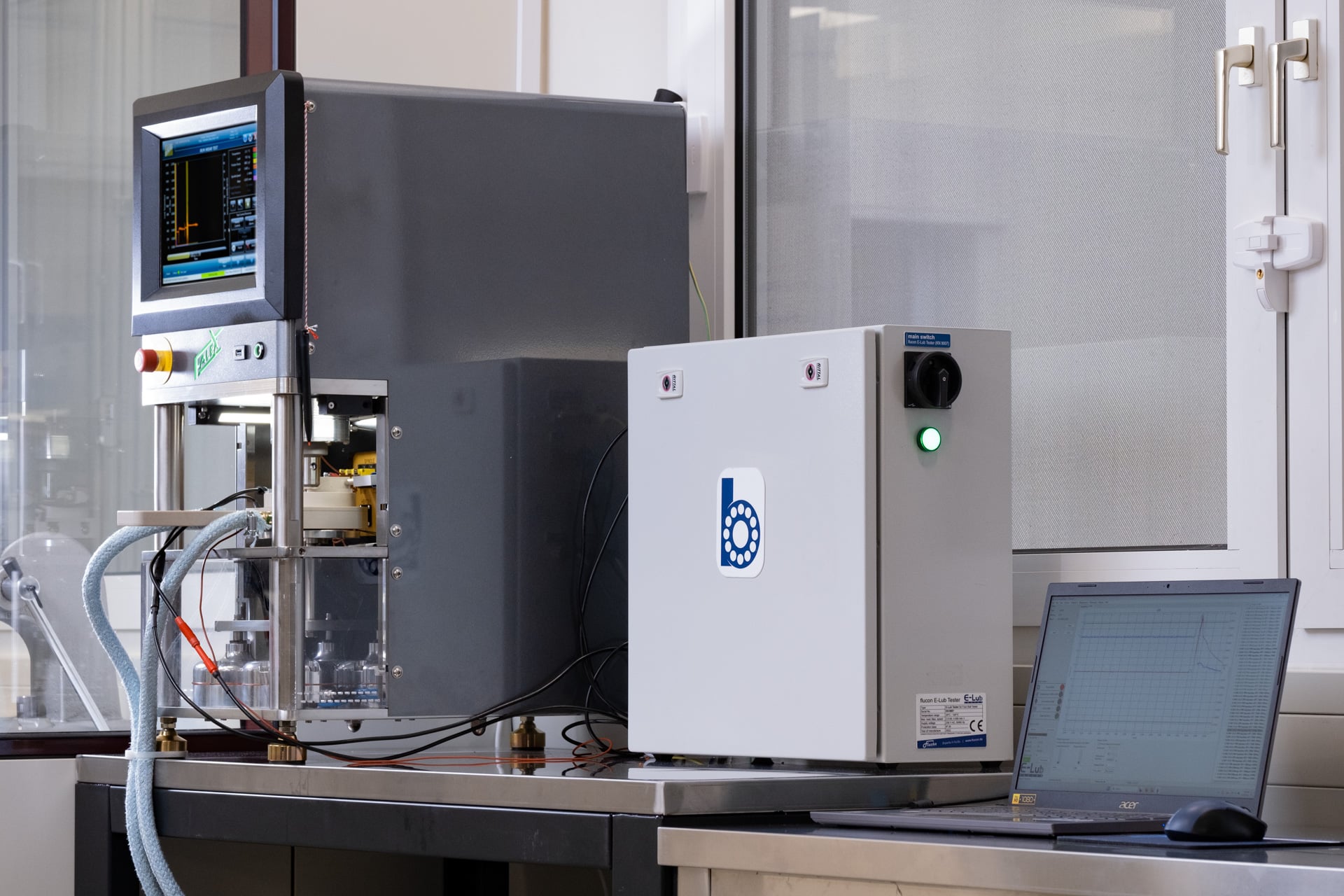

flucon's all-new Dielectric Tribometer: a test rig for lubricant impedance and breakdown measurement in bearings by use of a four-ball tester

The E-Lub Tester determines the ohmic resistance and capacitance of a test bearing and of the lubricant used therein under real operating conditions applied by a four-ball tester.

For this, a high-precision impedance measurement is used, which was developed based on flucon's EPSILON+ laboratory instrument.

In addition, the E-Lub Tester will analyze "EDM" breakdown currents and the dielectrical strength under a defined electrical load that is applied directly to the test bearing, so that the performance and discharge tendency of oils and greases can be investigated under fully variable operating conditions (lubricant temperature, speed, load).

Key features

- measuring adapter for Falex Four-Ball & Hansa VKA four-ball tester

- Impedance Test Mode: measurement of the lubricant impedance in a test ball bearing, determination of ohmic resistance and capacitance for each operating point

- Breakdown Test Mode: measurement of electrical discharges and ohmic currents during operation, full statistical analysis (number of discharges, average power)

- test cell for axial ball bearings (standard: type 51208), optionally radial ball bearings (type 6008) or roller bearings

- variable operating parameters: via E-Lub Tester: lubricant temperature (automatic control), electrical load (common-mode voltage); via FBT: running time, speed, axial load (all logged in test report)

- automated and semi-automated test campaigns

- includes intuitive software for control and measurement with a Windows PC

- includes impedance calibrator

Main components

The E-Lub Tester consists of two main components: the FBT adapter serves as the test cell, which contains the thrust ball test bearing as well as the impedance and temperature sensors. When inserted into the four-ball tester, it replaces the traditional four-ball setup.

The control cabinet complements the composition. It holds the impedance meter and the signal generator as well as additional electronics for precise application of the electrical load and for the analysis of the breakdown tendency.

The control cabinet complements the composition. It holds the impedance meter and the signal generator as well as additional electronics for precise application of the electrical load and for the analysis of the breakdown tendency.

A fluid circulator is used as a thermostat and can be connected to the FBT adapter for automated temperature control of the bearing and its lubricant.

With the included PC software each test can be carried out automatically within a desired temperature range.

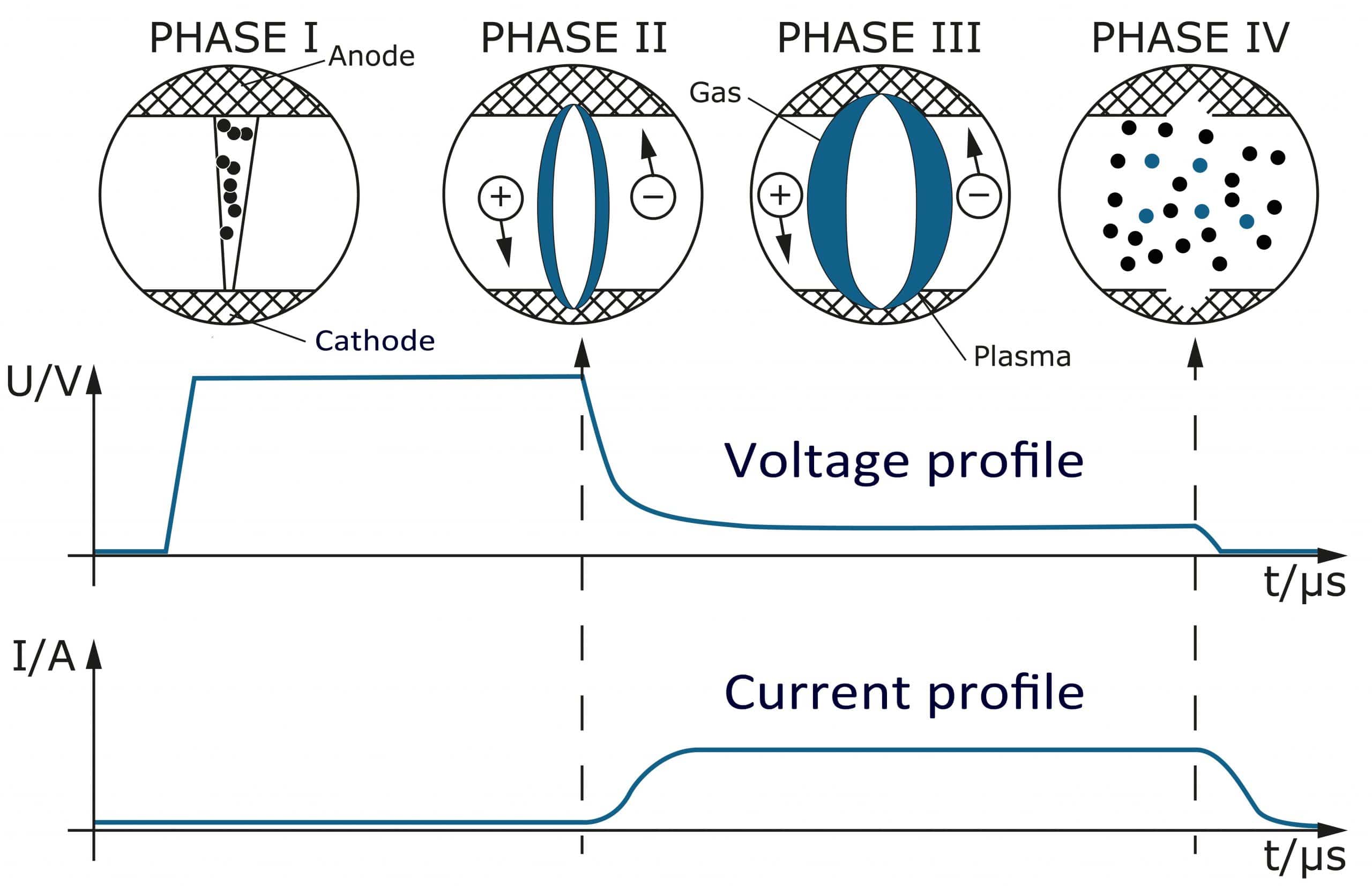

Background: breakdown currents in the lubrication gap

With the electrification making bigger progress every day, the electrical and dielectric properties of oils and greases used in the electric driveline are becoming more and more important. Lubricants in anti-friction bearings must have a certain specific electrical conductivity so that static charges and resulting electrical breakdowns can be minimized to prevent damage to both bearings and lubricants.

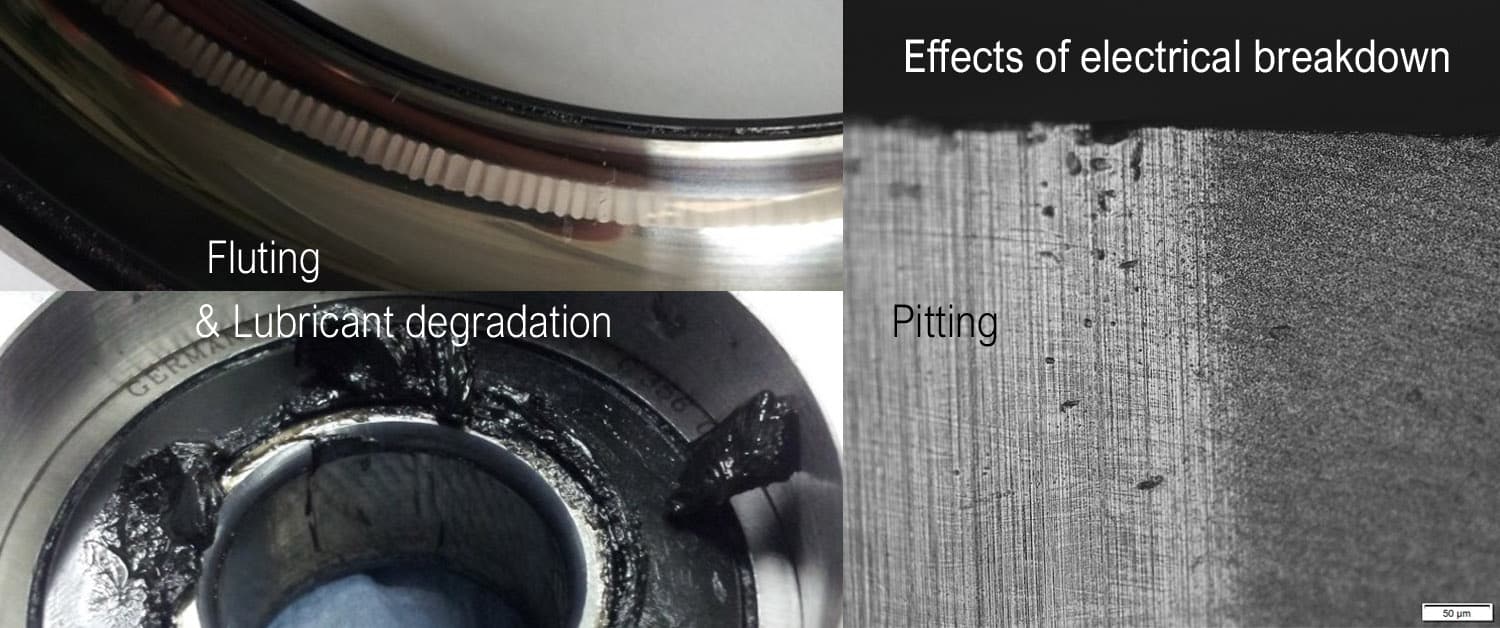

While the effects of harmful discharges in the electric drive have been documented for many years, the targeted investigation of such bearing-based spark erosion that was given the analogy of "Electric Discharge Machining (EDM) effects" has just now been made possible.

In addition to friction, electrical breakdowns occuring in rolling and ball bearings are a common phenomenon of frequency inverter-controlled drives that cause considerable damage to the bearing shells: sudden discharges with strong currents caused by high potential discrepancies due to the insulating lubricant film will lead to pitting damage, i.e. crater and corrugation formations, but also to fluting and grayfrosting in the raceway.

Furthermore, the lubricant will age excessively when exposed to breakdown current flow: local overtemperatures in the lubrication film will cause permanent damage to greases and oils so that the lubrication is severely affected.

A new dynamic method: Impedance measurement on lubricated bearings under real-life conditions - with laboratory-like accuracies

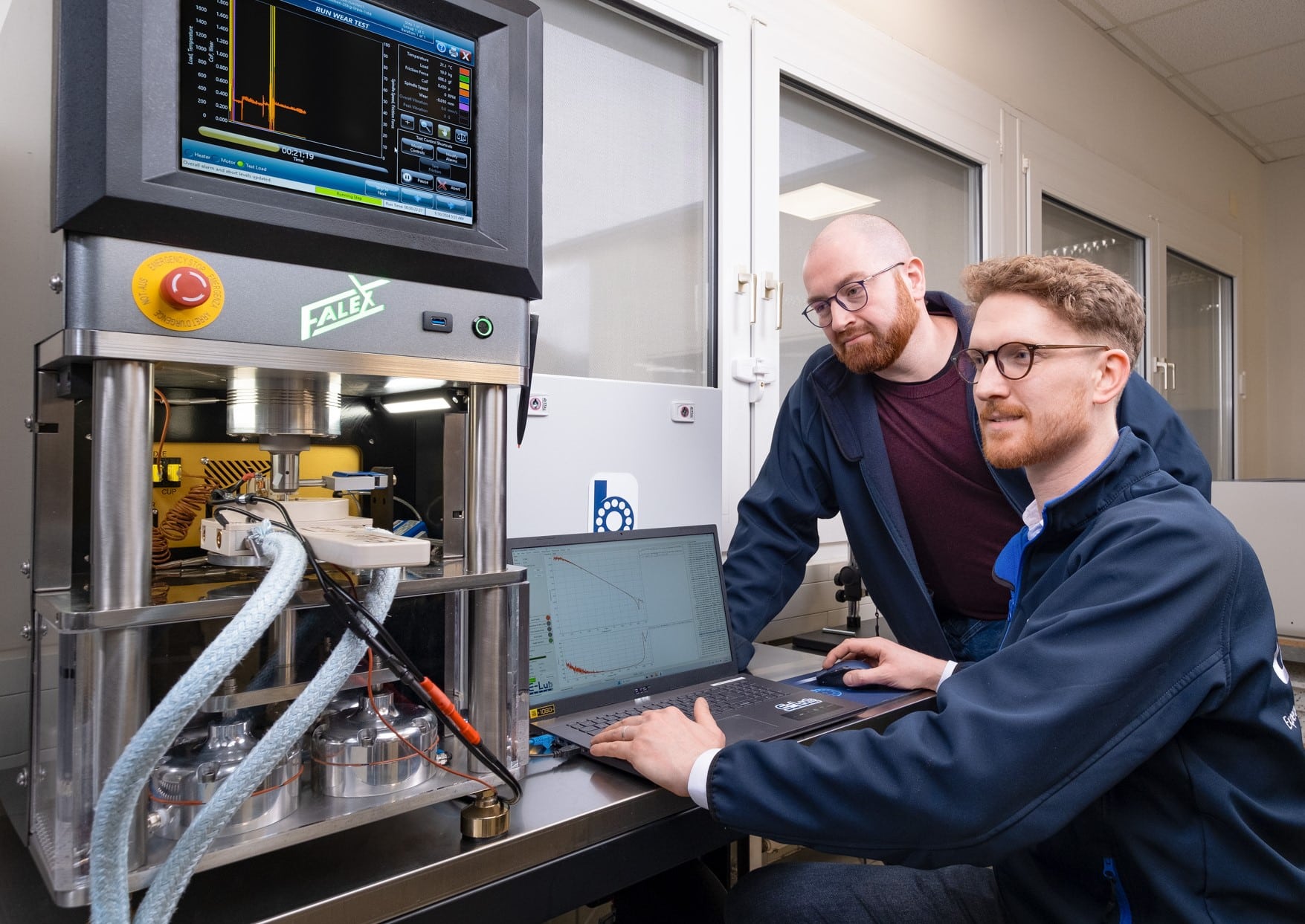

With flucon's E-Lub Tester it is now possible to determine the lubricant impedance and breakdown tendency directly in the bearing, under real process conditions. The proven technology of the EPSILON+ Dielectricity Meter is used for highly accurate measurement.

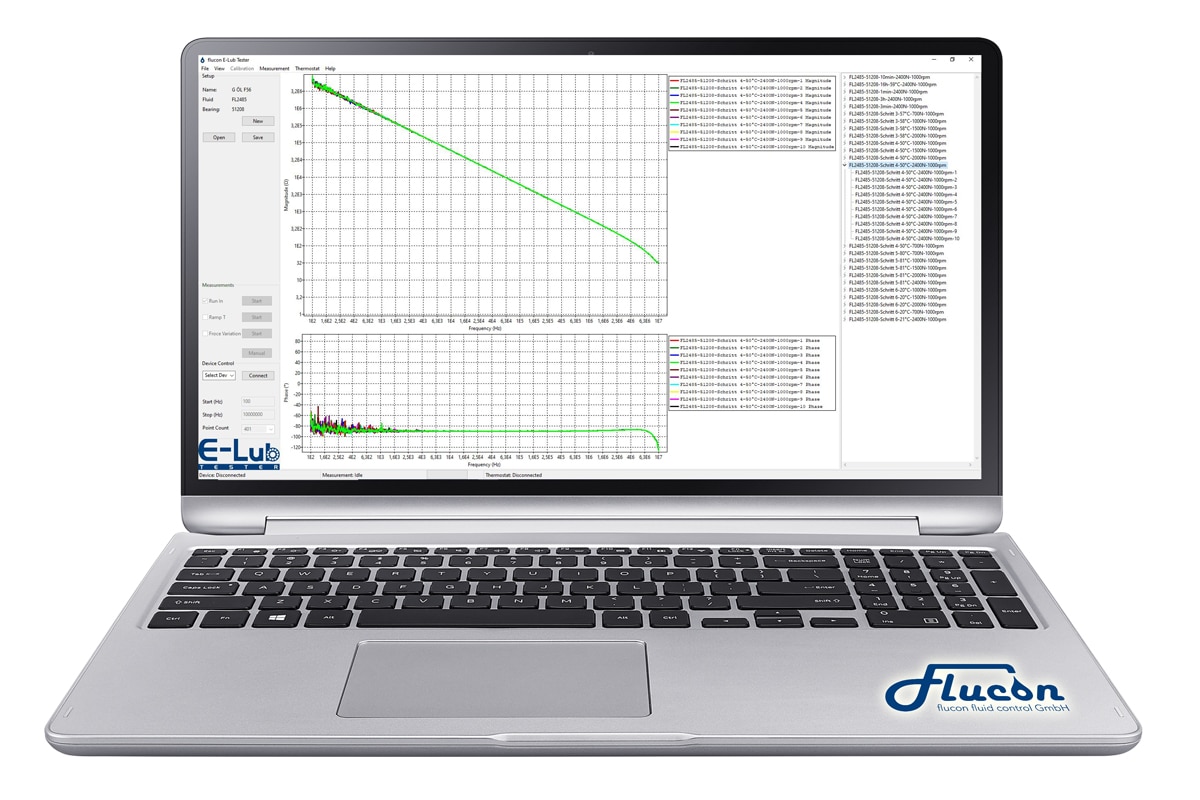

Intuitive software for guided and automated testing

Both the Impedance Test and the Breakdown Test of your lubricant are carried out automatically, thanks to the included software for your Windows PC. Here, various standardized and custom test modes are available.

Fields of application

The characteristic data generated with the E-Lub Tester can be used in lubricant development as well as for the following exemplary applications, where electric discharges play an important role:

- electric motors with variable speed

- e-mobility

- gear technology

- railway technology

- wind turbines

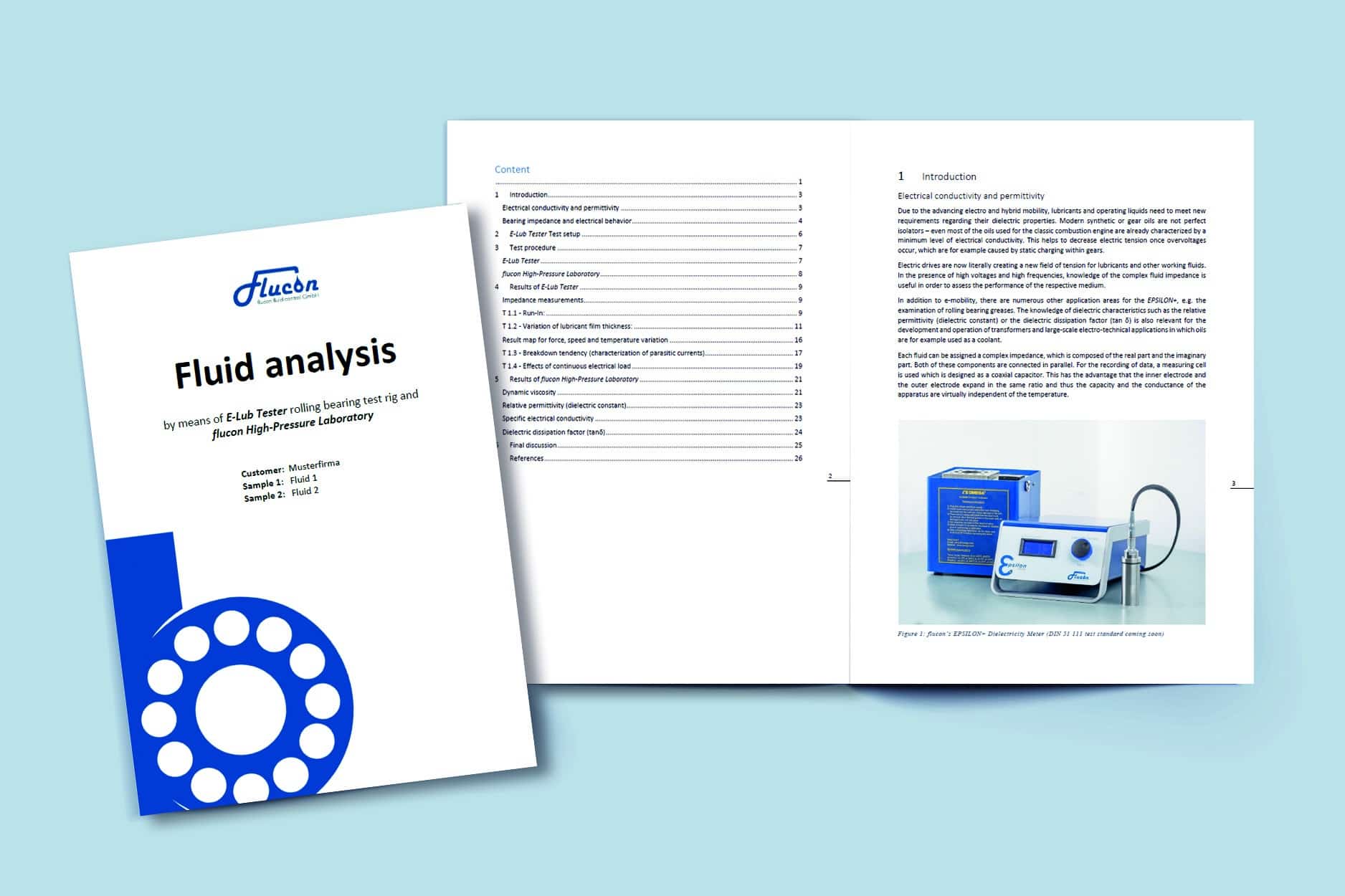

Available now: In-house demo and service testing

On request, we can carry out measurements for you using our in-house equipment. This is, of course, possible according to the draft standard or also with individual boundary conditions suitable for you (with variable filling quantity, temperature, speed, load, applied voltage signal, running time).

Simply send in your lubricant sample and receive an extensive test report within a few work days.

Any questions about the test services by means of our E-Lub Tester? Please do not hesitate to contact us!

Technical specifications - E-Lub Tester

| Compatible FBT models | Falex Four-Ball, Hansa VKA-110 |

| Determined data | ohmic resistance, capacitance, breakdown frequency (number & amplitude of EDM currents) |

| Compatible substances | Greases and oils |

| Bearing types | 51208 (optionally: 6008) |

| Material - FBT adapter | stainless steel with PEEK housing and assembly handle |

| Temperature measurement | PT100 by bearing |

| Temperature range | 20°C to 120°C |

| Load | 2.400 N max. |

| Speed | 6.000 rpm max. |

| Frequency range | 100 Hz to 10 MHz |

| Common-Mode Voltage | 60 V max. (peak to peak) |

| Connectivity | USB, ethernet |

| Power supply | 230 V AC, 50/60 Hz |

| Scope of delivery | FBT-adapted bearing test cell with sensor cables, mounting mandrel & ball, control cabinet, "flucon E-LUB" PC software (for Windows OS) |

| optional accessories | Fluid thermostat w/ compressor, set of hoses, laptop |