Bearing impedance measurement

Basics of measuring the impedance of roller bearings with E-Lub Tester

Each lubricant has a specific electrical conductivity and a relative permittivity, also known as "dielectric constant".

Both quantities can be determined by determining the complex impedance of the substance; this is composed of the real part on the one hand and the imaginary part on the other. In the equivalent circuit, an ohmic resistance and a capacitance are obtained, which are connected in parallel.

Figure: 51208 roller bearing with RC circuits (15 balls will lead to 15 x 2 dielectric lubricant films that are measured in parallel) [flucon GmbH 2025]

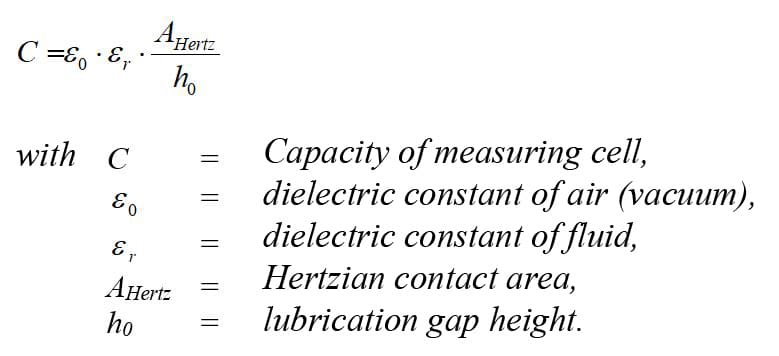

Independent of the bearing type (axial/radial), the following formula results for the capacitive behavior of the bearing:

The electrical resistance is also calculated by the following formula:

The complex impedance is measured by applying a low alternating voltage that does not cause an electrical breakdown. The current is measured according to magnitude and phase.

For the measurement of the dielectric constant, the imaginary part is decisive. Therefore, it is favorable to select a high frequency for the measurement of the dielectric constant. For the measurement of the specific conductivity, on the other hand, a low frequency is favorable, since the imaginary part becomes small and thus the decisive real part predominates.

This applies to a defined operating condition or to a fixed geometry. In the bearing, these can vary greatly due to the wide range of applications.

The test cell (bearing pot) of the E-Lub Tester was therefore designed in such a way that the real operating range of electric drives can be reproduced by varying the temperature, axial load and speed. Each of these parameters will affect the lubricant film and its thickness h_min. This in turn influences the ohmic and capacitive behavior, which can be seen on the following graph by means of drifts.

Therefore, the impedance measurements are conducted over a defined frequency range (100 Hz to 10 MHz), performing Electrical Impdeance Spectroscopy (EIS), to allow a qualified evaluation.

The temperature dependency of the dielectric properties of fluids under laboratory conditions can be determined using the EPSILON+ laboratory dielectricity meter.

Combining the static method of EPSILON+ with the dynamic tests of E-Lub Tester, flucon's Dual Approach opens up new possibilities for assessment of the lubrication condition and the lubricant film thickness given in a lubricated bearing under real-life conditions.

Precise temperature control is a must for the E-Lub Tester due to the high dependency of both the electrical properties and the viscosity. The test cell contains optimized cooling channels and is connected to a powerful Julabo Magio circulator. The temperature measurement inside the cell is realized with two integrated Pt100 sensors.

The device consists of an in-house developed impedance meter in a 19" rack that is connected to a PC with the flucon E-Lub Tester software.

After adjusting speed and/or axial load, a thermal equilibrium is set by means of a Julabo Magio thermostat before each measurement to ensure the highest possible measurement accuracy.

Isotherms of the impedance curve in the desired frequency spectrum can be recorded with standardized measurement campaigns.