FOAM Flucon Oil Aeration Machine

When aeration is a challenge, FOAM may be your solution.

The appearance of entrained gas in operating media such as lubricants or hydraulic oils may cause functional problems and even damage in many technical applications. As a consequence to the general pursuit of compactness and high efficiency, fluids are exposed to growing strains, which increases the risk of entrained air accumulating in the medium. Aerated oils lose their lubricity and get compressible, which may cause serious tribological problems or even damage to power-transmitting components.

The appearance of entrained gas in operating media such as lubricants or hydraulic oils may cause functional problems and even damage in many technical applications. As a consequence to the general pursuit of compactness and high efficiency, fluids are exposed to growing strains, which increases the risk of entrained air accumulating in the medium. Aerated oils lose their lubricity and get compressible, which may cause serious tribological problems or even damage to power-transmitting components.

flucon, who have become a top-notch expert in the field of two-phase flow testing ever since we developed the CGS Inline Aeration Meter over a decade ago, have designed a reliable and patented test rig for the controlled introduction of air into non-conductive fluids, allowings customers to counteract the problems arising from trapped gas in their lubricated or hydraulic systems.

flucon's latest innovation: FOAM Aeration Test Rig

FOAM (Flucon Oil Aeration Machine) is a compact aggregat which can be connected to your test tank (FOAM XL-x version) where it then produces consistent air-in-oil dispersions.

If you favor a stand-alone test rig with an integrated heatable 40 Liter tank, we recommend the FOAM S version. If more than 60 l/min (15 gpm) of aerated oil are required, we also offer extra-large custom FOAM units.

No matter what type of FOAM you prefer: Aeration testing is very easy with this plug-and-play unit. Simply set up the gas concentration (CG set = 0.50 - 25.00 vol.-%*) for your specific oil. The FOAM will add the desired amount of dispersed gas to your fluid promptly. This procedure will be carried out automatically, with no compressed air supply required. Once the gas concentration reaches the required level the "FOAM ready" lamp will light up and you can go ahead and pump the aerated oil through your circuit.

No matter what type of FOAM you prefer: Aeration testing is very easy with this plug-and-play unit. Simply set up the gas concentration (CG set = 0.50 - 25.00 vol.-%*) for your specific oil. The FOAM will add the desired amount of dispersed gas to your fluid promptly. This procedure will be carried out automatically, with no compressed air supply required. Once the gas concentration reaches the required level the "FOAM ready" lamp will light up and you can go ahead and pump the aerated oil through your circuit.

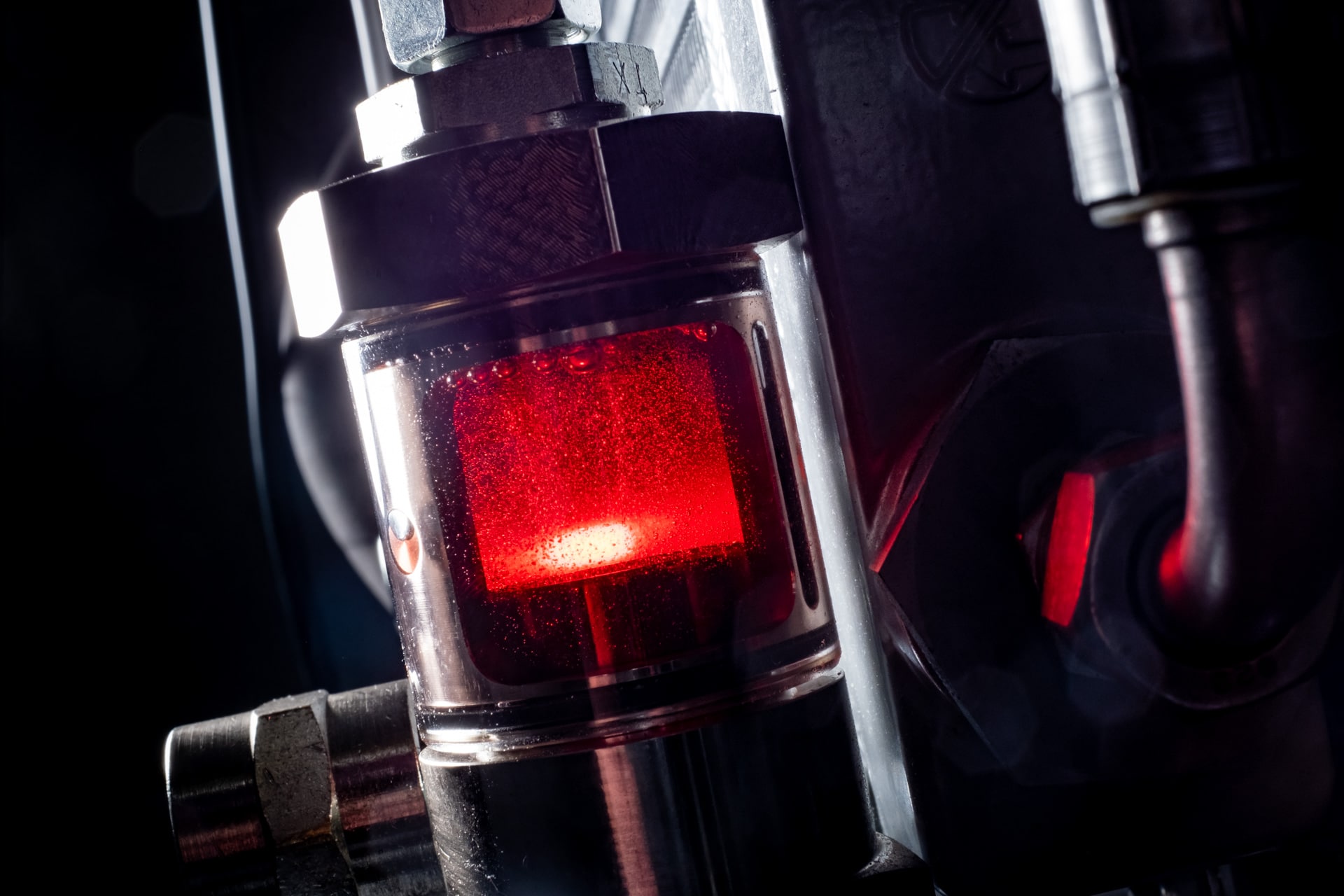

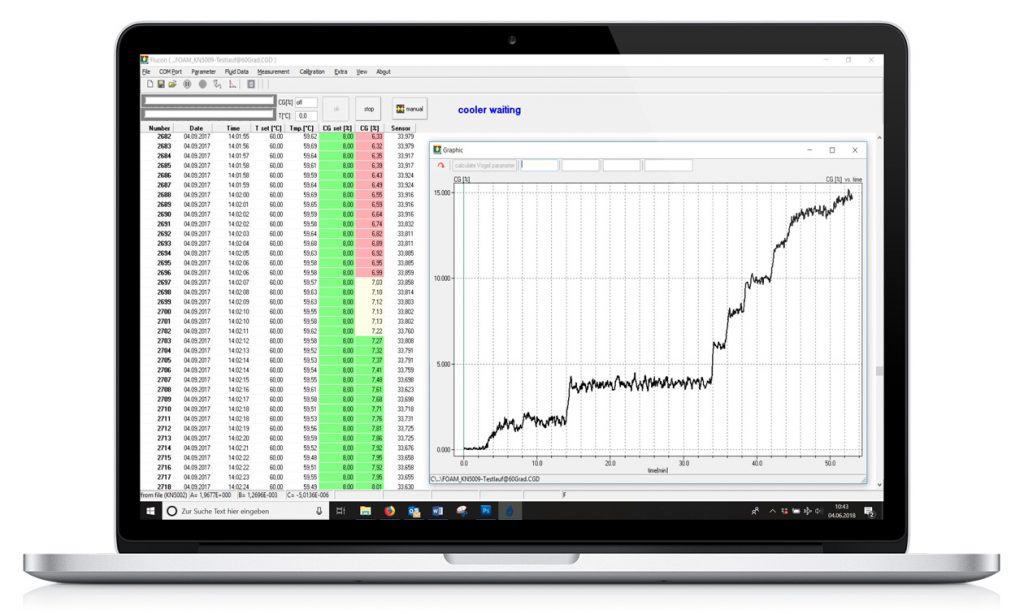

Since both the natural degassing and the consumption of your test application will reduce the gas concentration of your aerated mixture, there is an automatic degassing compensation based on live CG measurement. After the FOAM has been calibrated on the fluid of your choice, it constantly measures the live gas concentration inside your tank and intelligently inserts additional air to keep the CG on a constant level. The integrated sight glass (FOAM S) visualizes the dispersion and lets you keep an eye on the homogeneity of your two-phase mixture.

The temperature control compensates for the heat which is generated through the aeration process. If you go for the FOAM S you can also heat up the oil in preparation for your tests by means of its built-in 4.5 kW heater.

FOAM | General features

- continuous production of consistent and homogenous air-in-oil dispersions (micro-bubble mixtures)

- adjustable gas concentration (CG) 0.50 ... 25.00 vol% (* max. CG depends on viscosity and additives)

- automatic degassing compensation function based on live 1 Hz CG measurement

- integrated temperature control w/ air cooler (4.5 kW heater for FOAM S only)

- fully applicable to your fluid circuit or test bench

- no compressed air supply needed

- easy integration through external setup (FOAM XL-x) or included reservoir (FOAM S)

- highly accurate integrated aeration sensor (no additional sensor required)

- simple handling and compact size (mobile unit on wheels)

- analog interface (0...10 V) for all process parameters and for external control

- sight glass for aeration visualization (FOAM S)

- can be used for multiple oils (requires single calibration for each new fluid used)

- successfully tested with many motor oils, transmission fluids, CVT fluids etc.

- standard digital interface (RS-232) for an optional connection to your Windows PC (intuitive fluconFOAM software included)

FOAM | Versions

(1) Standard: FOAM XL-x - external aeration test rig

- external aeration unit with hoses or pipes connected to your own reservoir

- CG Set = 0.00 ... 25.00 vol% (in 0.50 vol% increments)

- 3-phase motor 400 V 50-60 Hz; high efficiency (IE3)

- suitable for flow rates of up to 60 l/min (custom units for higher rates are also available)

- accurate CG control: external aeration measurement within the suction area of your test object

- fast and reliable CG measurement at atmospheric pressure

- continuous circulation for homogenous and stable results

- approx. measures: L 850 mm x D 750 mm x H 1100 mm; weight: approx. 180 kg

- scheme of potential setup (your additional components represented on the left):

(2) FOAM S - stand-alone version

- stand-alone aeration test rig

- continuous production of temperature-controlled micro-bubble mixtures

- CG Set = 0.00 ... 25.00 vol% (in 0.50 vol% increments)

- includes 40 Liter reservoir (requires approx. 20 l min.)

- suitable for flow rates of up to 50 l/min

- 3-phase motor 400 V, 50-60 Hz; high efficiency (IE3)

- comes with 4.5 kW heater and air cooler (T set = 20 ... 120°C)

- integrated CG measurement

- approx. measures: L 880 mm x D 800 mm x H 1100 mm, weight: approx. 200 kg

- additional pump required (built-in pump will be used for internal circulation only)

- full control via stand-alone mode, RS-232/USB with flucon software or 0...10 V analog interface

- scheme of possible application (your additional components represented on the left):

Ready to aerate?

Whatever works best for your aeration test bed - we're here to help you and find individual solutions. Get in touch now and learn more about FOAM and its various functions and possibilities. If you would like to get further information and a non-binding quotation, simply follow the link below to make an inquiry today.

Control your aeration, solve your problems.

Are you interested in aeration testing with FOAM? Contact us now for further information and a non-binding quotation.

We are looking forward to your inquiry!

Experts in fluids. Experts in aeration.